Common Pump Failures Predictive Tech Solves

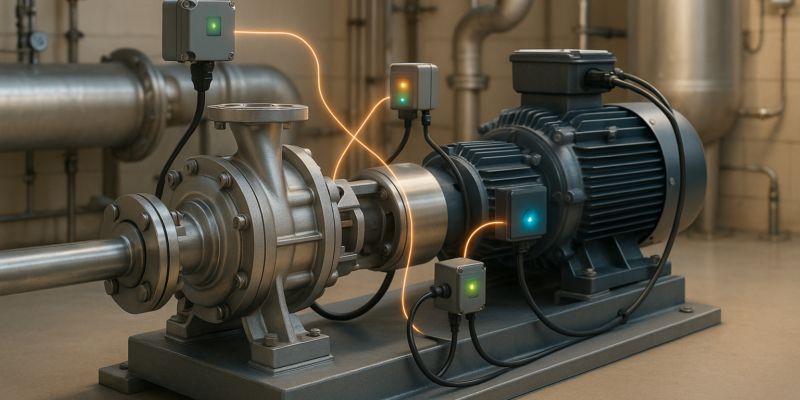

Predictive maintenance is transforming how pumps are managed by identifying potential failures before they occur. Using IoT sensors, real-time data, and AI, this approach monitors critical factors like vibration, temperature, and pressure to prevent costly breakdowns. Key benefits include:

- Cost Savings: Reduces maintenance expenses by up to 30% and downtime by 45%.

- Improved Reliability: Detects issues like bearing wear, seal leaks, cavitation, motor overheating, and blockages early.

- Better Performance: Extends pump lifespan and minimizes disruptions.

For example, a chemical plant reduced pump failures by 40%, while vibration monitoring saved an oil plant over $100,000 by catching a faulty bearing early. Predictive maintenance is reshaping pump care, offering smarter, data-driven solutions for long-term efficiency.

#NIWeek2016: IoT enables smart pump conditioned monitoring

Common Pump Failures That Predictive Technology Prevents

When it comes to pump systems, understanding their most frequent failures is key to appreciating the impact of predictive maintenance. These failures aren’t just inconvenient – they can lead to performance issues, increased costs, and even safety risks. Here’s a closer look at the most common pump failures and how predictive technology helps tackle them head-on.

Bearing Wear and Failure

Bearing issues are the leading cause of pump breakdowns, responsible for 40–50% of failures. Worn bearings often result in increased vibration and noise, clear indicators of impending failure. The main culprit? Loss of lubrication, which leads to damaging metal-on-metal contact.

Predictive maintenance addresses this by using vibration and temperature sensors. These sensors monitor vibration patterns and detect heat increases that signal lubrication problems or contamination in the bearings. By focusing on frequencies in the 20–500 Hz range and measuring vibrations across all three axes, predictive systems can also catch misalignment issues early – another factor that accelerates bearing wear.

Seal Leakage Problems

Seal failures rank as the second most common pump issue, causing 20–25% of failures. These problems lead to fluid loss and often point to deeper issues within the pump.

“Seal failure is often a symptom of an underlying problem within the pump.” – Bob Goodenberger, John Crane

Predictive technology identifies seal issues by monitoring vibrations and pressure changes that indicate internal leaks. Temperature sensors can pick up heat buildup near seals, while pressure monitoring reveals instability affecting sealing surfaces. For instance, cavitation – a condition where vapor bubbles collapse violently – can produce pressure pulsations that damage seals. Catching these issues early not only prevents costly repairs but also avoids environmental and regulatory consequences.

Cavitation and Impeller Damage

Cavitation is another common issue, causing 10–15% of pump breakdowns. This occurs when pressure drops create vapor bubbles that collapse, producing shock waves that erode impellers and other components. Predictive systems detect cavitation by analyzing vibration data (1,000–1,500 Hz), along with temperature and pressure readings. These systems can also monitor for shaft imbalances and pressure drops that signal impeller damage.

Impeller damage itself accounts for 5–10% of pump failures. By catching early warning signs like unusual noises, reduced efficiency, or increased vibration, maintenance teams can address problems before they require a full impeller replacement.

Motor Overheating

Motor overheating contributes to 5–10% of pump failures. When motors overheat, they can seize up, leading to expensive repairs or complete replacements. Predictive maintenance combats this with thermal monitoring and electrical signature analysis (ESA). Temperature sensors detect rising heat levels before they become critical, while ESA monitors voltage and current to spot electrical or mechanical issues. These tools also track the motor’s current draw, which increases when pumps face resistance from blockages or other issues, ensuring problems are resolved before they escalate.

Blockages and Flow Problems

Blockages are a serious concern, as they disrupt performance and can trigger a cascade of failures across the pump system. They force motors to work harder, strain seals, and can even lead to dry running conditions that destroy components in minutes.

Predictive maintenance systems are equipped to detect blockages by monitoring changes in vibration, pressure, temperature, and electrical current. Electrical signature analysis is particularly effective, as it identifies how a motor’s electrical signals shift when pumps encounter resistance. For example, in England, nearly 20% of combined sewer overflow incidents occur at pumping stations, underscoring the importance of blockage prevention.

How Predictive Maintenance Solves Pump Problems

Predictive maintenance uses advanced monitoring systems to identify potential pump issues before they lead to expensive breakdowns. Let’s dive into the key methods it employs and how each tackles specific pump problems.

Vibration Analysis for Mechanical Problems

Vibration monitoring is a cornerstone of predictive maintenance, as it identifies mechanical issues well before they escalate. By tracking vibrations against predefined baselines, this method can pinpoint problems like bearing wear, misalignment, cavitation, and impeller imbalance. For instance, an imbalanced impeller often results in increased vibration at the machine’s running speed (1X vibration), while misalignment might reduce vibration amplitude due to added structural stiffness. Placing sensors along the shaft centerline ensures multi-directional vibration data is captured. Advanced techniques like shock pulse analysis can even detect early signs of bearing wear.

Temperature monitoring adds another layer of protection by identifying overheating risks.

Temperature and Thermal Monitoring

Thermal sensors play a critical role in spotting overheating before it causes irreversible damage. They can detect lubrication breakdown or contamination – two factors that often lead to bearing failure. In fact, more than 50% of motor failures stem from bearing problems caused by lubrication loss or contamination. To ensure accuracy, sensors should be placed on components where temperature changes are likely to occur first. Over-temperature relays and sensors provide additional safeguards, alerting operators to overheating or heat generated by seal leaks during seal failure.

Flow and pressure monitoring complement thermal data by highlighting operational irregularities.

Flow Rate and Pressure Monitoring

Monitoring flow rate and pressure is essential for detecting blockages and maintaining pump efficiency. These parameters provide real-time insights into the pump’s condition. Flow rate monitoring measures the volume of liquid or gas moving through the system over time. Any deviations in flow or pressure trigger alarms, allowing operators to address blockages or other issues before they worsen. As the PumpWorks Engineering Team explains:

“Predictive monitoring involves using analytic technology to check pump performance in real time.”

Pressure monitoring works hand-in-hand with flow data, identifying issues like blockages, seal failures, or cavitation.

Machine learning takes these monitoring methods to the next level by analyzing data for deeper insights.

Machine Learning and Predictive Algorithms

The real strength of predictive maintenance lies in machine learning. These algorithms analyze historical data to improve prediction accuracy and detect subtle anomalies that might escape human observation. By distinguishing between normal operational variations and genuine warning signs, machine learning helps prevent unexpected downtime. For example, one manufacturing plant reduced maintenance costs by up to 25% by using these algorithms to optimize scheduling and resource allocation. With IoT sensors continuously feeding data into these systems, maintenance teams can act at the perfect time to avoid failures.

Comparing Different Maintenance Approaches

When it comes to maintenance strategies, facility managers face the challenge of balancing timing, cost, and performance. Each approach offers distinct methods and financial implications.

Reactive vs. Preventive vs. Predictive Maintenance

Reactive maintenance is all about fixing equipment after it breaks, which often leads to steep costs. Preventive maintenance, on the other hand, involves scheduled servicing to avoid potential problems. Predictive maintenance takes it a step further by using real-time data to determine the best time for interventions.

The financial impact of these strategies is worth noting. Preventive maintenance can save businesses between 12% and 18% compared to reactive methods, while predictive maintenance offers even greater savings – up to 40%. For facilities in the U.S., where unplanned equipment downtime can cost an average of $260,000 per hour, these savings are critical.

| Maintenance Strategy | Cost Impact | Downtime Risk |

|---|---|---|

| Reactive | Low upfront, but costly long-term due to emergency repairs | Very high |

| Preventive | Moderate upfront with solid ROI, based on scheduled servicing | Medium |

| Predictive | Higher upfront but delivers the best ROI, leveraging data for precise timing | Low |

The advantages of predictive maintenance go beyond cost savings. As Oriental Motor explains:

“The idea behind predictive maintenance is that you can make more informed data-driven decisions to replace components at exactly the right time.”

Preventive maintenance often relies on manufacturer-provided lifespan estimates, which can result in replacing parts prematurely. Predictive maintenance, however, uses real-time sensor data to focus solely on components that are actually nearing failure.

Modern monitoring systems boast up to 95% accuracy, with the ability to predict failures up to a year in advance. This approach not only extends equipment lifespan by 20% but also reduces risks related to safety, health, environment, and quality by 14%.

The adoption of predictive maintenance is growing rapidly. In North America alone, it accounts for an estimated 31.67% of the market share. Predictive analytics delivers a tenfold return on investment and cuts costs by 30% to 40%.

For pump systems specifically, predictive maintenance reduces both downtime and unnecessary part replacements. Unlike preventive maintenance – which can involve labor-intensive disassembly of complex systems – predictive methods target only the components that require attention. This precision lowers labor costs, minimizes disruptions, and supports the integration of IoT solutions while aligning with U.S. pump maintenance standards.

sbb-itb-99db659

How to Implement Predictive Maintenance

Implementing predictive maintenance for pump systems involves careful planning and the integration of advanced technology. This includes upgrading existing equipment with smart sensors, adhering to industry standards, and working with skilled professionals to ensure systems run efficiently and reliably.

Adding IoT Sensors to Existing Systems

The process of retrofitting IoT sensors begins with identifying operational priorities. Choosing the right hardware for the environment is key, factoring in installation simplicity, power availability, and reliable communication options.

Vibration sensors play a critical role in predictive maintenance by detecting even the smallest changes in vibration patterns. These sensors should be installed following established protocols – such as Zigbee, LoRaWAN, or Wi-Fi – and mounted with vendor-approved kits to guarantee consistent performance.

Once installed, sensors are typically connected to a cloud-based system that collects and analyzes real-time data. Machine learning algorithms process this data to identify unusual patterns, triggering alerts when maintenance is required. Using open-source middleware and robust APIs ensures smooth data sharing between IoT devices and existing maintenance management systems.

The benefits of IoT platforms in predictive maintenance are clear. For example, facilities have seen unplanned downtime drop by 27% and annual maintenance costs decrease by nearly 19%. Additionally, API-driven IoT solutions have led to a 15% increase in component lifespan and a 22-hour reduction in the average time needed for repairs.

To minimize disruptions, it’s best to coordinate sensor installations during scheduled facility shutdowns. Training maintenance teams on installation techniques and safety protocols helps ensure sensors are accurately positioned and data quality remains high. Once installed, testing the system to confirm proper data flow to cloud or edge platforms is essential. Any issues should be documented and resolved promptly. Finally, verifying compliance with US standards ensures the system meets regulatory requirements.

Meeting US Standards and Regulations

Predictive maintenance must align with both US and international standards. For vibration analysis, ISO 20816 provides guidelines for measurement and evaluation, ensuring consistent monitoring across pump systems. In thermal monitoring, technicians certified under ASNT TC-1A are recognized for their expertise in infrared thermography. Similarly, oil analysis often follows ISO 4406 standards for particle counting, ensuring accurate contamination tracking.

Organizations are encouraged to start with a pilot project, which includes evaluating current practices, selecting suitable technologies, and building the necessary data infrastructure. This approach lays the groundwork for long-term compliance and operational success. Partnering with professional service providers can further ensure these standards are met and systems perform as intended.

Working with Professional Service Providers

Once the technology and regulatory framework are in place, collaborating with experienced service providers can enhance the effectiveness of predictive maintenance systems. Companies like Hydrodynamics specialize in pump maintenance for residential, commercial, and industrial clients, offering services that include installations, repairs, and energy-efficient solutions.

“Predictive maintenance isn’t just about monitoring – it’s about preventing failures before they occur. With IoT-predictive insights, businesses can anticipate equipment issues, schedule maintenance proactively, and maximize uptime.”

– Greg Tankersley, President of Becker Engineered Systems

Professional providers bring valuable expertise to the table, especially when retrofitting sensors into various pump configurations. They manage technical challenges like ensuring compatibility with legacy systems, using tools such as Modbus-to-MQTT bridges to avoid data silos. By prioritizing open standards and proven technologies, these experts help future-proof investments and maintain the effectiveness of predictive maintenance systems.

Working with knowledgeable professionals ensures minimal disruption during sensor installations while delivering measurable improvements in system performance and reliability.

The Future of Pump Maintenance

The way we approach pump maintenance is undergoing a major transformation, thanks to predictive technologies that shift the focus from fixing problems after they occur to preventing them in the first place. Predictive maintenance has proven to be a game-changer, reducing machine downtime by 30–50%, extending equipment lifespan by 20–40%, cutting labor costs by 25–30%, and improving energy efficiency by 5–15% by keeping machinery running at peak performance. For instance, a leading oil refinery used machine learning to prevent equipment failures, saving up to $1 million annually. And this is just the beginning – new technologies are poised to take pump maintenance to the next level.

Emerging Technologies Driving Change

Digital twins are one of the most exciting developments in this space. These virtual replicas of physical assets simulate wear and tear in real time, helping predict issues before they happen. Edge computing is also making waves, enabling real-time data analysis even in remote areas with limited connectivity. Meanwhile, deep learning algorithms are improving the ability to detect patterns in sensor data, and autonomous drones are simplifying inspections in hard-to-reach locations.

The Internet of Things (IoT) is another driving force behind these advancements. By 2025, edge computing is expected to process nearly half of enterprise data, enabling faster decision-making. Companies already leveraging AI-powered predictive maintenance are seeing maintenance costs drop by 10–20%.

Industry Success Stories

Some of the biggest names in the industry are showcasing just how impactful these technologies can be. Rolls-Royce has cut engine maintenance costs by 30% using IoT sensors and digital twins. ThyssenKrupp has boosted service reliability by 50% with IoT-connected predictive maintenance. And Shell has managed to decrease equipment downtime by 20% by employing sensor-driven predictive analytics. These successes highlight the potential for organizations willing to embrace these advanced methodologies.

Getting Started with Predictive Maintenance

For companies looking to make the leap, the first step is to focus on critical assets and set clear goals and performance benchmarks. Training maintenance teams and establishing strong communication between maintenance, operations, and management are also essential for long-term success.

Specialized companies like Hydrodynamics can help organizations implement these systems effectively. Their expertise in installations, repairs, and energy-efficient solutions ensures that businesses not only maximize the benefits of predictive maintenance but also meet US standards and regulations.

“Predictive maintenance empowered by IoT data is no longer optional – it’s essential for companies aiming to remain competitive and cost-effective.”

- Kevin Ashton, technology pioneer who coined the term “Internet of Things”

This shift toward predictive maintenance is more than just adopting new tools – it’s a strategic decision that sets organizations up for long-term success in a demanding and competitive industrial world. By investing in these technologies, companies can stay ahead of the curve and achieve operational excellence.

FAQs

How do IoT sensors and AI-powered predictive maintenance help prevent common pump issues like bearing wear and seal leaks?

IoT sensors combined with AI-driven predictive maintenance systems tackle common pump problems like bearing wear and seal leaks by keeping a close eye on equipment performance in real time. These systems gather detailed data on critical factors such as vibrations, temperature, and noise levels, spotting even the smallest changes that could hint at potential issues.

AI steps in with advanced algorithms to analyze both historical and live data, uncovering patterns that might indicate a failure before it happens. This proactive approach means maintenance can be scheduled at the right time, helping to avoid sudden breakdowns, cut down on repair expenses, and extend the working life of your pumps. By catching problems early, these technologies help ensure your equipment runs smoothly and efficiently.

What are the key steps to start using predictive maintenance for existing pump systems?

How to Implement Predictive Maintenance for Pump Systems

Getting started with predictive maintenance for your pump systems begins with a thorough review of your equipment. Document everything – model numbers, age, maintenance history, and current condition. This process helps you pinpoint potential failure points and sets a benchmark for tracking performance over time.

The next step is installing sensors to gather real-time data. Common options include vibration sensors to monitor mechanical health, thermal sensors to track temperature changes, and ultrasonic detectors for detecting early signs of wear or leaks.

Once the data starts flowing, make sure it becomes a seamless part of your maintenance operations. Integrate it into your workflows so you can spot issues early and act before they escalate. To make the most of this approach, focus on three key areas:

- System Compatibility: Ensure the sensors and software work with your existing setup.

- Team Training: Equip your staff with the knowledge they need to use and interpret the new technology.

- Clear Protocols: Establish guidelines for analyzing data and taking action when irregularities are detected.

By following these steps, you can improve system performance and cut down on costly downtime. Predictive maintenance not only keeps your pumps running smoothly but also saves time and resources in the long run.

What are the cost and downtime benefits of predictive maintenance compared to reactive and preventive approaches?

Predictive maintenance offers a smarter, more effective alternative to reactive and preventive methods. By spotting potential problems before they happen, it can slash unplanned downtime by 50-75% and cut maintenance expenses by 18-30%. On top of that, it can extend the lifespan of equipment by 20-40%, making it a savvy choice for businesses looking to optimize long-term performance.

What sets predictive maintenance apart is its use of advanced algorithms to keep tabs on equipment in real time. Unlike reactive maintenance, which only kicks in after something breaks, or preventive maintenance, which follows a fixed schedule, predictive maintenance takes a proactive approach. This means fewer disruptions and smoother operations, ultimately saving businesses both time and money.