PEX vs. Copper: Leak Prevention Comparison

What’s better for preventing leaks: PEX or copper pipes?

Here’s the quick answer:

- PEX pipes are flexible, resist freezing, and have fewer joints, which lowers the risk of leaks. But they’re prone to UV damage and require precise installation.

- Copper pipes are durable, handle high pressure and temperatures, and resist bacterial growth. However, they can corrode in certain water conditions and are more likely to crack in freezing temperatures.

Quick Comparison:

| Feature | PEX | Copper |

|---|---|---|

| Leak Prevention | Fewer joints, corrosion-resistant | Durable, antimicrobial, but more joints |

| Lifespan | 30–50 years | 50–70 years |

| Installation | Faster, simpler, fewer tools | Slower, requires soldering |

| Cost | $4,000–$8,000 for a 2,000 sq. ft. home | $8,000–$16,000 for a 2,000 sq. ft. home |

| Freeze Resistance | Flexible, less likely to crack | Rigid, higher freeze risk |

Both options have pros and cons. PEX is affordable and quick to install, while copper is a long-term, recyclable option. Your choice depends on your budget, local water conditions, and durability needs.

PEX vs COPPER for Plumbing – Which Should You Use and …

How PEX and Copper Prevent Leaks

PEX and copper pipes each have unique characteristics that help reduce leaks. Here’s a closer look at how these materials work to keep your plumbing secure.

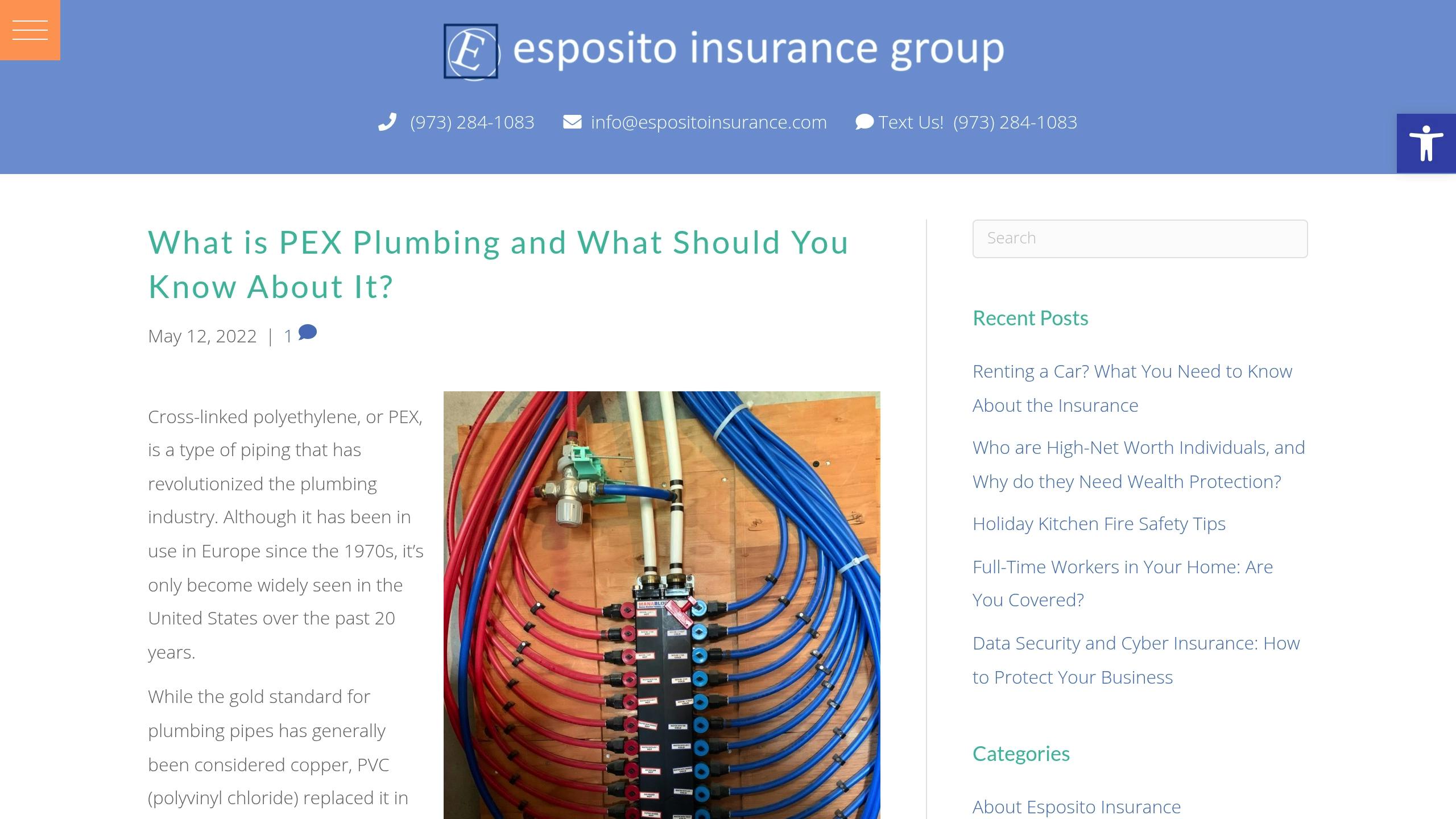

PEX Pipe Features

PEX pipes are flexible, which means fewer joints and weak spots in your plumbing system. They are also resistant to corrosion, making them a durable choice for many applications.

However, PEX has some drawbacks:

| Limitation | Impact on Leak Prevention |

|---|---|

| UV Sensitivity | Prolonged exposure to sunlight can weaken the material. |

| Physical Damage | Can be damaged by sharp objects or improper handling. |

| Connection Quality | Requires precise installation to ensure fittings are secure. |

Copper Pipe Features

Copper pipes are strong and durable, making them capable of handling high pressure and temperature changes. They also have natural antimicrobial properties, which help prevent bacterial growth and reduce the risk of corrosion.

Despite these advantages, copper has its own challenges:

| Consideration | Impact on Leak Prevention |

|---|---|

| Water Chemistry | Certain water types can cause copper to corrode over time. |

| Freeze Risk | Copper is more likely to crack in freezing temperatures. |

| Joint Requirements | More connections are needed, increasing potential leak points. |

Setup and Upkeep

When it comes to installation and maintenance, PEX and copper pipes have distinct requirements, each playing a key role in preventing leaks over time.

PEX Installation Steps

PEX installation is simpler and requires fewer tools compared to copper. Its manifold system, with fewer joints, minimizes potential leak points by centralizing distribution.

| Installation Aspect | Details | Impact on Leak Prevention |

|---|---|---|

| Tool Requirements | Crimping tool, pipe cutter, calibration tool | Ensures secure connections via crimping |

| Connection Method | Compression or expansion fittings | Fewer joints reduce leak risks |

| Time Investment | Faster than copper installation | Lowers chances of installation mistakes |

| Space Requirements | Flexible routing around obstacles | Reduces strain on fittings and joints |

To avoid leaks:

- Keep to the recommended bend radius (usually 6–8 times the pipe diameter)

- Use fittings approved by the manufacturer

- Account for expansion and contraction

- Shield pipes from UV exposure

On the other hand, copper installation follows a more detailed and skill-intensive process.

Copper Installation Steps

Installing copper pipes requires expertise, especially for soldering, which is critical for leak prevention.

| Installation Aspect | Details | Impact on Leak Prevention |

|---|---|---|

| Tool Requirements | Torch, flux, solder, pipe cutter, cleaning tools | Proper soldering prevents joint failures |

| Connection Method | Soldered joints or mechanical fittings | Precision is key for each joint |

| Time Investment | Slower, with curing time needed | Ensures durable and reliable connections |

| Space Requirements | Rigid routing with exact measurements | Strategic joint placement reduces stress |

Important maintenance steps for copper systems include:

- Inspect soldered joints regularly

- Watch for signs of corrosion

- Test water pH levels periodically

- Address issues like water hammer promptly

Both systems benefit from professional installation to maximize leak prevention. Next, we’ll explore how these installation differences affect durability and strength.

Life Expectancy and Strength

Durability plays a major role in preventing leaks. Let’s break down how PEX and copper hold up over time to help you make an informed choice.

PEX Lifespan

When installed correctly, PEX pipes can last between 30 and 50 years. Their flexible design helps absorb the impact of water hammer and freezing, which reduces the likelihood of leaks. Plus, the smooth interior resists scaling, keeping water flowing efficiently.

Here’s how PEX performs:

- Temperature: Works well under typical household conditions.

- Pressure: Handles standard residential water pressure without issues.

- Chemical Resistance: Stands up to chlorine and acidic water.

Copper Lifespan

Copper pipes have an impressive lifespan of 50 to 70 years. Their rigid structure tolerates high pressure and temperature changes, making leaks less common. Additionally, copper’s natural resistance to corrosion contributes to its longevity.

Key copper traits include:

- Temperature: Can handle both extreme heat and cold.

- Pressure: Performs reliably under higher water pressures.

- Corrosion Resistance: Minimizes the risk of leaks over time.

Both materials can be affected by water quality and environmental factors. If the water is particularly aggressive, additional protective measures might be needed. For personalized advice on choosing the right plumbing system and ensuring proper installation, consider reaching out to the experts at Hydrodynamics.

Next, we’ll look at the costs and resource demands of each option.

Price and Resource Use

Costs depend on materials, installation, and long-term resource consumption.

PEX Costs

PEX is a budget-friendly option for both materials and labor. PEX piping costs range from $0.50 to $2 per linear foot, and installing a PEX plumbing system in a typical 2,000‑square-foot home costs between $4,000 and $8,000, including materials and labor.

Here’s what impacts PEX costs:

- Material Costs: PEX tubing is about one-third the cost of copper.

- Installation Time: Installing PEX is 40–50% faster than copper.

- Tool Costs: PEX tools run between $100 and $300 and can be reused.

- Maintenance: Requires minimal upkeep over time.

While PEX is affordable, its recyclability is limited. When it reaches the end of its lifecycle, it often ends up in landfills, which may be a concern for some.

Copper Costs

Copper systems come with higher upfront expenses but are durable and recyclable. Installing copper plumbing in a 2,000‑square-foot home typically costs between $8,000 and $16,000.

Copper cost factors include:

- Material Costs: Copper pipes cost $2.50 to $8 per linear foot.

- Labor Costs: Professional plumbers charge $45 to $150 per hour for installation.

- Joining Materials: Additional expenses for solder, flux, and fittings.

- Tools: Standard plumbing tools, which most contractors already have.

Although the initial investment is higher, copper boasts a recyclability rate of over 90%. Scrap copper sells for $2 to $3 per pound, making it a more resource-conscious option.

For tailored advice on the best plumbing solution for your home, Hydrodynamics offers detailed estimates and recommendations based on your property and local water conditions.

Conclusion

PEX and copper pipes each bring their own strengths to leak prevention. PEX is a popular choice for residential projects due to its flexibility and affordability, while copper is often selected for its long-lasting performance in demanding environments. The right choice depends on your budget, the complexity of the installation, and specific application requirements.

Hydrodynamics’ certified technicians can evaluate factors like water quality, pressure, and local regulations to ensure your plumbing system is installed correctly. Whether you’re starting a new project or upgrading an existing system, they offer services for residential, commercial, and industrial needs.

Reach out to Hydrodynamics for expert advice and support.