What Happens During an HVAC Energy Audit?

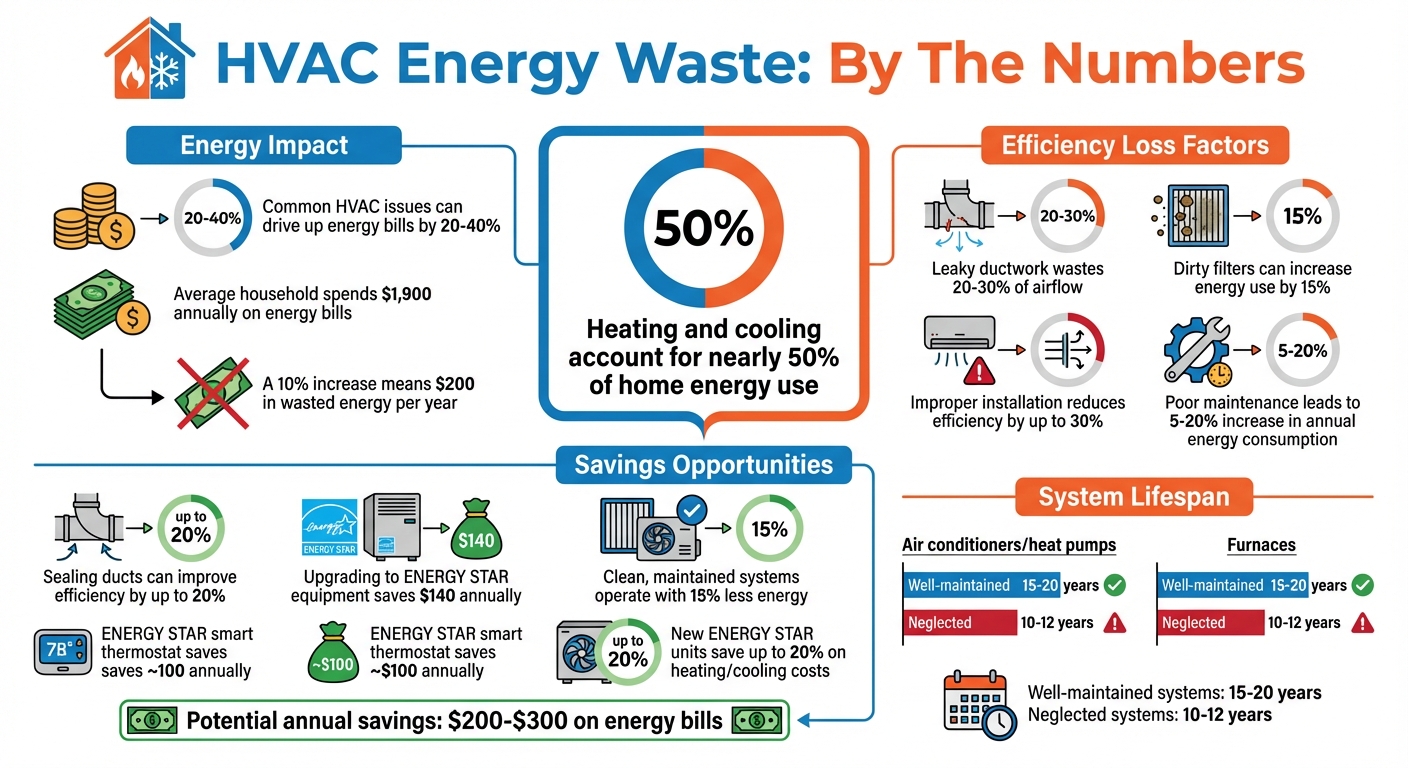

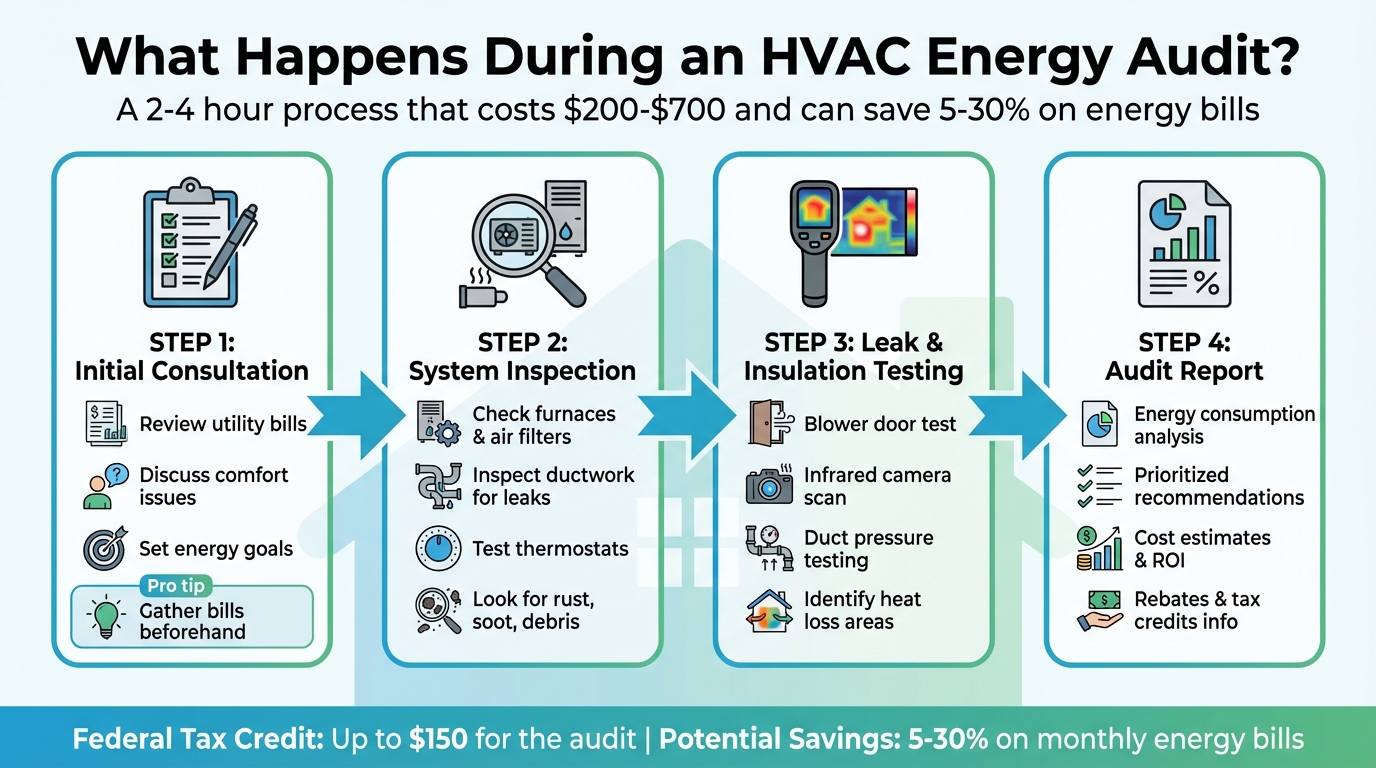

An HVAC energy audit evaluates your home’s heating, cooling, and ventilation systems to identify energy waste and recommend cost-saving improvements. Here’s what to expect:

- Initial Consultation: Review utility bills, discuss comfort issues, and set goals.

- System Inspection: Check HVAC components like furnaces, air filters, ductwork, and thermostats for inefficiencies or safety concerns.

- Leak and Insulation Testing: Use tools like blower doors and infrared cameras to locate air leaks and insulation gaps.

- Performance Testing: Measure airflow, duct pressure, and HVAC efficiency.

- Audit Report: Receive a detailed report with recommendations, cost estimates, and potential savings.

Audits typically last 2–4 hours, cost $200–$700, and can qualify for a federal tax credit of up to $150.

HVAC Energy Audit Process: 4 Main Steps from Consultation to Report

Main Steps in the HVAC Energy Audit Process

Initial Consultation and Information Gathering

Before diving into the technical aspects, the process kicks off with a conversation. The auditor will review your home’s energy usage over the past year, analyzing utility bills to identify trends and seasonal spikes in consumption . This step helps establish a baseline and provides insight into how your energy use fluctuates throughout the year.

During this consultation, you’ll also have a chance to share any concerns about your home’s comfort. Maybe you’ve noticed drafty rooms, windows fogging up with condensation, or areas that never seem to stay comfortable no matter the season . The auditor will also ask about your goals – whether you’re looking to cut energy costs, improve indoor air quality, or make targeted upgrades within a specific budget .

“A professional energy assessment can provide an expertly designed roadmap to saving money and improving the comfort of your home.” – U.S. Department of Energy

Pro tip: Gather your utility bills and jot down any comfort issues ahead of time. This preparation ensures you won’t forget to mention anything important and helps the auditor work more efficiently .

Once this discussion wraps up, the auditor moves on to a detailed inspection of your HVAC system.

Physical Inspection of HVAC Components

Next comes a hands-on examination of your heating and cooling equipment. The auditor will inspect the age of your system and check burners for signs of trouble, such as soot, rust, or debris. These issues often hint at reduced efficiency or potential safety risks .

They’ll also inspect blower wheels and air filters, as dust accumulation can choke airflow and drag down efficiency. Ductwork gets a close look too. Dirt streaks near seams often signal air leaks, and in unconditioned spaces like attics, they’ll check whether ducts are properly insulated. Lastly, they’ll test thermostats and safety controls to ensure your system cycles on and off correctly.

With the HVAC system reviewed, the focus shifts to the building’s insulation and air tightness.

Testing for Air Leaks and Insulation Problems

To identify where your home may be losing energy, the auditor uses a blower door test. This involves placing a fan in an exterior doorway to lower indoor air pressure, making leaks easier to detect. Infrared cameras are then used to scan walls, floors, and ceilings, highlighting areas where heat escapes or where insulation is lacking .

They may also perform duct pressure tests to pinpoint leaks within the ductwork. These leaks can waste a surprising amount of energy, making them critical to address. Together, these diagnostic tools provide a clear picture of where improvements are most needed.

Once leaks and insulation issues are identified, the auditor moves on to evaluate your system’s overall performance.

System Performance Testing

Performance testing is where the auditor measures how well your HVAC system is functioning. Using furnace efficiency meters, they’ll analyze flue gas composition and temperature to ensure combustion safety. They’ll also check airflow rates, duct pressure, and temperature differences to determine how efficiently your system distributes conditioned air.

Additional tools, like surface thermometers and smoke pens, help detect drafts or subtle heat losses within the system. These tests reveal whether your HVAC equipment is performing as expected or if factors like poor maintenance, incorrect installation, or age are holding it back.

The results from these tests are compiled into a detailed audit report, which outlines specific recommendations for improving your home’s energy efficiency.

sbb-itb-99db659

How to Perform a Whole-House Energy Audit | Ask This Old House

Types of HVAC Energy Audits

Energy audits come in various forms, each tailored to different needs and budgets. The American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) outlines three distinct levels of audits, ranging from quick assessments to detailed studies. These levels help you choose the right approach based on your goals and financial considerations.

Level 1: Basic Walkthrough Audit

A Level 1 audit is the most straightforward and cost-effective option, typically costing about $0.12 per square foot. It involves a quick walkthrough of your home, a review of utility bills, and a discussion about any noticeable comfort issues. The focus is on identifying obvious problems and simple, cost-effective fixes – often referred to as “low-hanging fruit.”

This type of audit provides a preliminary assessment, offering rough estimates for costs and potential savings. It’s a great starting point to decide if a more detailed audit is worth pursuing. As a general guideline, the total cost of an energy audit should not exceed 10% of your annual utility expenses.

Level 2: Detailed Energy Analysis

For a deeper dive, a Level 2 audit offers a more thorough evaluation, priced at approximately $0.20 per square foot. This option includes detailed energy usage breakdowns and diagnostic tests, such as airflow measurements and leak detection. The auditor may suggest operational adjustments, like optimizing thermostat settings, and more significant upgrades, such as improving insulation or replacing outdated equipment.

“If a Level 1 audit is about examining an HVAC system’s current performance, then a Level 2 audit is about improving that performance for sustainability’s sake.” – Air Comfort

This level is ideal for homeowners who are ready to act on specific recommendations. It delivers actionable insights with clear cost-benefit analyses, making it easier to prioritize efficiency upgrades.

Level 3: Advanced Engineering Study

The most comprehensive option, a Level 3 audit, costs around $0.50 per square foot. Known as an investment-grade audit, this approach includes advanced techniques like detailed modeling, hourly energy simulations, and life-cycle cost analysis. It’s designed to provide precise return on investment (ROI) estimates, helping justify major system upgrades or overhauls.

“A Level 3 audit is a refined analysis and expands to include additional measurements, testing, modeling, and life-cycle cost analysis to inform decision making.” – ASHRAE

While this level of detail is generally unnecessary for most homeowners, it’s invaluable for those planning significant HVAC system investments. For standard residential needs, Level 1 or Level 2 audits typically offer sufficient insights for making informed efficiency improvements.

What You Receive: The Audit Report

What’s Included in the Report

After the on-site inspection and testing, the auditor compiles all findings into a comprehensive report. This report highlights your home’s potential for energy savings and includes key details like building characteristics – square footage, wall area, window types, and insulation status. It also features an energy consumption analysis, reviewing your utility bills to pinpoint when and where energy is being wasted.

You’ll find documentation of problem areas, such as thermographic images that reveal heat loss and blower door test results showing air leaks. Additionally, the report addresses any health and safety concerns, including issues like moisture, mold, or carbon monoxide. In some cases, the report may also provide a Home Energy Score, which rates your home’s energy efficiency.

“A home energy assessment helps you learn how you use energy, determine where it’s being wasted, and prioritize efficiency upgrades.” – Energy Saver

These findings are based directly on the inspections and tests conducted during the audit.

Recommended Improvements and Cost Estimates

Using the audit results, the report provides a clear plan of action to improve your home’s energy efficiency. Each recommendation is prioritized and comes with a cost-benefit analysis. Whether it’s air sealing, duct insulation, or upgrading your HVAC system, the report includes estimated costs, projected energy savings, and payback periods. This helps you identify the upgrades that offer the best return on investment.

Making these improvements can lead to savings of 5% to 30% on your monthly energy bills. The report also highlights available utility rebates, tax credits, and financing options to help reduce the upfront costs of upgrades. Federal tax credits may also apply, as outlined in the report . Air sealing and insulation are often recommended as top priorities since they deliver immediate comfort and significant energy savings with a relatively low initial cost.

Next Steps After Your Audit

With your audit report in hand, it’s time to roll up your sleeves and put the plan into action. Think of your report as a personalized guide, highlighting where energy is being wasted and which upgrades will give you the best bang for your buck. The real magic happens when you use that roadmap to make changes. As Energy Saver points out, “Making the recommended energy efficiency upgrades is what leads to energy savings”.

Start with safety. If your audit flagged any health or safety concerns – like carbon monoxide leaks, moisture problems, or mold – these should be your top priority. Addressing these issues promptly ensures your home is safe before moving on to efficiency improvements. Once safety is taken care of, tackle the simpler fixes first. Air sealing and adding insulation are great starting points. These upgrades often bring immediate improvements in comfort and energy savings without requiring a hefty investment.

For more complex tasks – like sealing ducts, resizing systems, or replacing an HVAC unit – it’s wise to bring in a professional. A qualified HVAC expert, such as Hydrodynamics, can ensure the work is done correctly and meets industry standards. This not only boosts the performance of your system but also helps extend its lifespan, aligning with the recommendations from your audit.

Don’t forget about financial incentives. You might be eligible for a federal tax credit of up to $150 just for the audit itself. On top of that, there are often utility rebates or tax credits for specific upgrades, like installing energy-efficient HVAC systems or improving insulation. These programs can make a big dent in your upfront costs, making it easier to invest in long-term savings.

Ready to take the next step? Contact Hydrodynamics to schedule your HVAC energy audit and start making your home more efficient today.

FAQs

What are the benefits of an HVAC energy audit?

An HVAC energy audit pinpoints areas where your heating and cooling system may be wasting energy and offers practical solutions to boost efficiency. By evaluating factors like air leaks, insulation, and overall system performance, the audit can reveal issues that inflate utility bills. In fact, addressing these problems can lead to energy savings of 5–30%. Recommendations often include sealing ducts, adding programmable thermostats, or upgrading to energy-efficient equipment – all steps that can improve comfort while lowering expenses.

But it’s not just about saving money. An energy audit can also enhance indoor air quality and safety. Using tools like infrared cameras and blower-door tests, professionals can uncover hidden problems such as air leaks, moisture issues, or even carbon monoxide risks. This process not only extends the lifespan of your HVAC system but can also make you eligible for utility rebates or tax credits, helping offset the cost of upgrades.

Hydrodynamics specializes in HVAC energy audits designed to reduce energy consumption, increase comfort, and cut costs. Scheduling an audit is a great way to take the first step toward a more efficient and comfortable home.

How should I get ready for an HVAC energy audit?

Preparing for an HVAC energy audit can make the process smoother and more effective. Start by gathering your utility bills from the past 2–3 months. These will give the auditor a clear picture of your energy usage patterns. Next, ensure there’s easy access to your HVAC equipment by clearing away any obstructions around air handlers, ductwork, and outdoor units.

Set your thermostat to “auto” and take note of any issues you’ve noticed, such as uneven temperatures, strange noises, or unexpectedly high energy bills. It’s also a good idea to jot down specific concerns or areas in your home that you think might need attention. These simple preparations can help the auditor pinpoint ways to boost your system’s efficiency and possibly lower your energy costs.

What steps should I take after receiving my HVAC energy audit report?

After receiving your HVAC energy audit report, take the time to go through it thoroughly. Look for specific issues like air leaks, gaps in insulation, or inefficiencies in your HVAC system. Make sure to note the recommendations tied to each problem.

Once you understand the findings, prioritize the upgrades based on factors like potential energy savings, cost, and how they’ll improve your comfort. High-priority tasks often include sealing air leaks, adding or upgrading insulation, or replacing old HVAC systems. Reach out to a professional contractor – Hydrodynamics is one option – to get estimates for these upgrades. Also, explore rebates, tax credits, or financing programs that could help reduce your out-of-pocket costs.

When you’ve mapped out your plan, schedule the upgrades and get the work done. Smaller tasks, like sealing minor leaks, can often be tackled as DIY projects. However, larger jobs, such as replacing an HVAC system or improving insulation, should be left to licensed professionals. After completing the updates, keep an eye on your energy bills and how comfortable your home feels to ensure the changes are making a difference. For extra reassurance, you might want to schedule a follow-up inspection to confirm everything is working as it should.