How to Spot HVAC Energy Waste

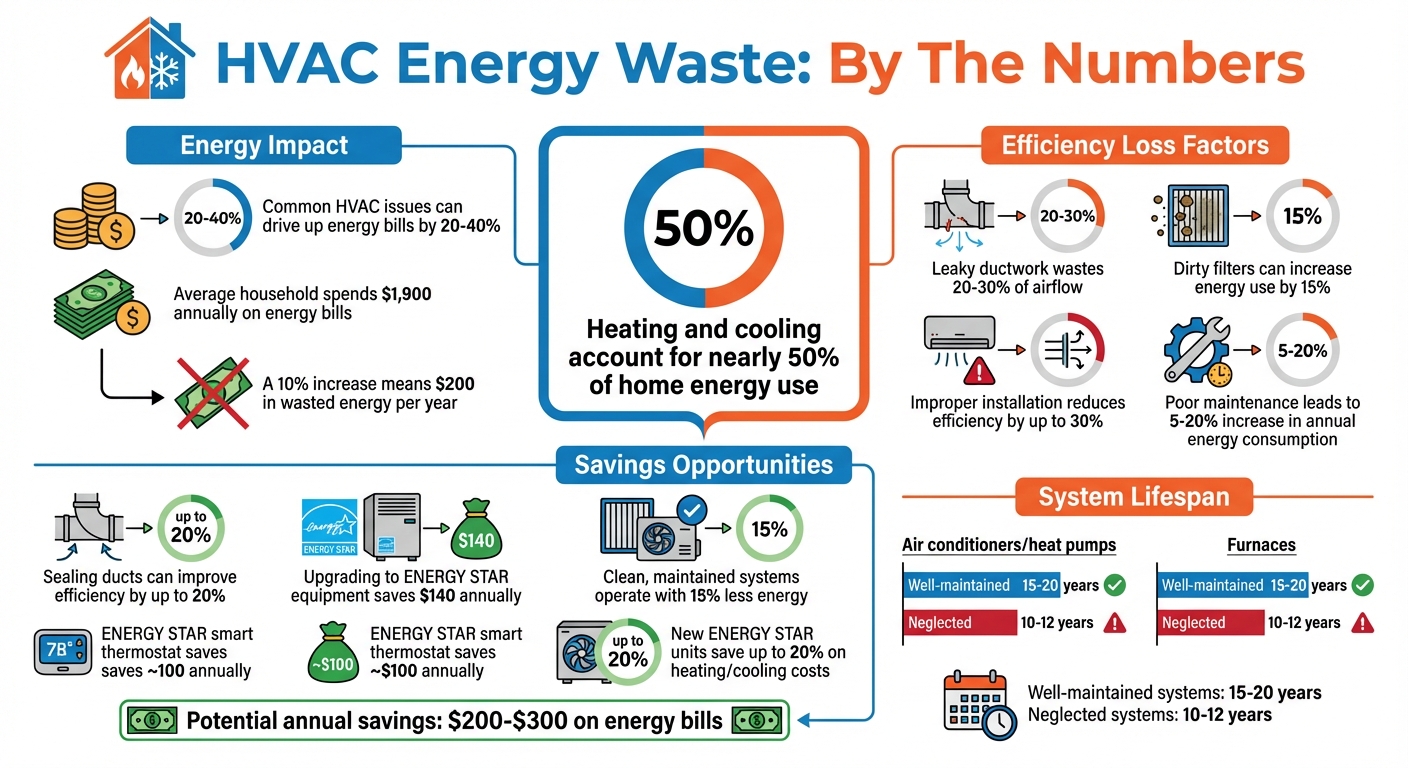

Your HVAC system could be wasting energy – and money – without you realizing it. Common issues like dirty filters, leaky ducts, and aging equipment can drive up energy bills by as much as 20%–40%. Heating and cooling account for nearly 50% of home energy use, making efficiency crucial for your comfort and wallet.

Here’s how to spot energy waste quickly:

- Check your utility bills: Compare costs month-to-month and year-to-year for unexplained increases.

- Inspect airflow and temperatures: Weak airflow, uneven room temperatures, or blocked vents signal inefficiencies.

- Listen and smell for warning signs: Unusual noises or odors often point to mechanical or electrical problems.

- Review the system’s age: Units older than 10–15 years lose efficiency and cost more to run.

- Maintain filters: Replace clogged filters every 1–3 months to avoid overworking your system.

Simple fixes like sealing ducts can improve efficiency by up to 20%, while upgrading to ENERGY STAR-certified equipment could save $140 annually. Regular maintenance and professional inspections can reduce energy waste and extend your system’s lifespan. Keep your HVAC system efficient to cut costs and stay comfortable year-round.

HVAC Energy Waste Statistics and Savings Opportunities

5 BIGGEST HVAC Energy Wasters Homeowners Don’t Know!

sbb-itb-99db659

Review Energy Bills for Unusual Increases

Your utility bill can be a goldmine of clues when it comes to spotting HVAC energy waste. The trick is knowing how to examine it and what patterns to look for.

How to Review Monthly Utility Statements

Start by pulling together your utility bills from the past 12 months. Compare each month’s bill to the same month from the previous year – like January 2026 against January 2025, or July 2025 versus July 2024. This approach accounts for seasonal differences in weather.

Pay close attention to high-demand months, such as winter and summer. Look for unexplained spikes in your bill that don’t align with changes in weather or usage. For example, if your January bill jumped from $180 last year to $245 this year, but your energy habits and the weather stayed consistent, it’s worth investigating.

Many utility companies now offer online tools or downloadable resources to help you track and analyze your energy usage over time. These tools can simplify spotting trends and irregularities. Considering that the average household spends about $1,900 annually on energy bills, even a modest 10% increase could mean nearly $200 in wasted energy each year.

If you notice unexplained increases, it’s time to dig deeper into potential issues with your HVAC system.

Common Signs of HVAC Energy Waste

When your bills rise unexpectedly, it’s often due to specific HVAC system problems. For instance, leaky ductwork can waste 20% to 30% of airflow, and clogged filters can restrict air circulation, forcing your system to work harder and consume more energy.

“A dirty filter will slow down air flow and make the system work harder to keep you warm or cool – wasting energy.” – ENERGY STAR

Another culprit could be improper installation of new equipment, which can reduce efficiency by up to 30%. Even if your system is brand-new, poor installation can lead to higher bills. Additionally, as HVAC systems age – typically beyond 10 to 15 years – their components naturally wear out, reducing efficiency and driving up energy costs. If you notice your bills creeping up year after year during the same seasons, it’s a sign your system might be struggling to keep up.

Check for Temperature and Airflow Problems

Uneven temperatures and weak airflow are clear signs your HVAC system might be wasting energy. If some rooms feel like a sauna while others are freezing, or if barely any air comes out of the vents, your system is likely overworking to compensate – pushing up your energy bills in the process.

These issues often point to duct leakage or pressure imbalances that disrupt air distribution. In fact, airflow problems alone can reduce your HVAC system’s efficiency by as much as 15%. The good news? You can spot these problems yourself with a few simple checks.

Measure Temperature Differences Between Rooms

Grab a digital thermometer and check the temperature in every room of your home. Jot down the readings and compare them to your thermostat’s setting. If you notice a difference of more than 3–5°F, you’ve likely uncovered an energy efficiency issue. Fixing these imbalances not only makes your home more comfortable but also helps cut down on wasted energy.

Large temperature differences often signal duct leaks or improper system sizing. An HVAC system that’s too large will cycle on and off frequently, failing to evenly distribute air. On the other hand, an undersized unit will struggle to maintain comfortable temperatures, running constantly without ever catching up.

For another quick test, place a glass thermometer next to your thermostat and leave it there for 15 minutes. If the readings differ by more than one degree, your thermostat might need recalibration. This could mean your system is kicking on unnecessarily, wasting energy every time it runs.

Test Airflow at Vents

Airflow testing is straightforward. Turn on your HVAC system, ensure all vents are open, and hold a piece of paper near each supply vent. The paper should flutter noticeably. If it barely moves – or doesn’t move at all – you’ve found an airflow problem.

Weak airflow can stem from several issues: a clogged air filter restricting circulation, dirty evaporator coils blocking airflow, or a failing blower motor struggling to push air effectively. These problems force your system to work overtime, wasting energy and wearing down components faster – which could lead to expensive repairs and a shorter system lifespan.

Here’s a quick breakdown of common symptoms, their causes, and how they impact energy use:

| Symptom | Potential Cause | Impact on Energy |

|---|---|---|

| Hot/Cold Spots | Leaky Ducts or Poor Insulation | High: Conditioned air escapes to unconditioned spaces |

| Weak Airflow | Clogged Filter or Failing Blower | Medium: System runs longer to reach the target temperature |

| Frequent Cycling | Oversized HVAC Unit | High: Increased wear and inefficient operation |

| Rattling Doors | Pressure Imbalance | Low/Medium: Air struggles to circulate properly |

Keep all vents open in every room. Closing vents might seem like a way to save energy, but it actually increases internal pressure in the system, making your HVAC work harder and less efficiently. Also, make sure vents are free from obstructions like furniture or curtains to allow air to circulate properly.

Identify HVAC Warning Signs

When it comes to spotting HVAC inefficiencies, don’t just rely on your bills or indoor temperatures. Pay close attention to what you can hear and smell – strange sounds and odors often hint at underlying issues that force your system to work harder than necessary. Unusual noises and odd smells are often early indicators of mechanical problems. Addressing these promptly can stop small issues from escalating into costly repairs.

“If you notice unusual sounds, schedule an inspection immediately.”

Taking preventive steps when these warning signs appear can improve your system’s performance by up to 45%. That’s not just a boost in efficiency – it’s also a noticeable decrease in your monthly energy costs.

Strange Noises from Your System

Every unusual sound your HVAC system makes tells a story, and unfortunately, it’s rarely a good one. Each type of noise often points to a specific problem that wastes energy. For example, whistling or wheezing could mean leaky ductwork or a clogged air filter, both of which restrict airflow. On the other hand, hissing often signals refrigerant leaks, which force the system to run longer to maintain desired temperatures. It’s worth noting that 20% to 30% of conditioned air is typically lost in homes due to duct issues.

Other sounds can indicate mechanical or electrical issues. Rattling or banging might mean loose parts like fan blades or motor mounts, or debris caught inside the system – problems that increase resistance and wear. Buzzing is often tied to electrical faults, such as failing contactors or loose wiring, which disrupt power flow and cause inefficiencies. Screeching or grinding may point to worn motor bearings or a slipping belt, both of which increase friction and energy consumption. Ignoring these issues can lead to expensive repairs, with AC motor fixes ranging from $300 to $600, and compressor replacements averaging $1,200.

If you hear a sharp, continuous squeal from your outdoor unit, it’s time to act fast. This could indicate dangerously high compressor pressure – turn the system off immediately. For noises like whistling or thumping, start by checking your air filter (refer to the air filter section for more details).

| Noise Type | Potential Mechanical Problem | Impact on Energy/Efficiency |

|---|---|---|

| Whistling | Leaky ducts, clogged filters | High energy waste |

| Hissing | Refrigerant or valve leak | Prolonged operation; increased waste |

| Screeching | Worn fan belt or motor bearings | Higher friction and power consumption |

| Buzzing | Electrical issues or failing fan | Inefficient power usage |

| Banging | Loose motor mounts or broken parts | Severe inefficiency; risk of failure |

Odd Smells from Vents

Unusual smells are just as telling as strange noises when it comes to spotting HVAC problems. For example, musty odors often mean mold caused by moisture buildup, which restricts airflow and increases energy use. Poor maintenance can lead to a 5-20% increase in energy consumption annually.

Burning smells are a red flag for electrical or overheating issues. These could stem from worn components or internal friction within motors, both of which drive up energy use and risk complete system failure. If you catch a burning smell, turn off the power at the breaker immediately to avoid potential electrical fires.

A sweet or chloroform-like scent might indicate a refrigerant leak. Since refrigerant is essential for heat transfer, even a small leak can force your system to run longer cycles, wasting significant energy. If this smell comes with hissing or bubbling noises, shut off the unit to prevent compressor damage.

“If the air is ten degrees or more warmer than normal and the filter is clean, refrigerant loss is likely.” – John Williams, Chief Executive Officer, Stan’s Heating, Air, Plumbing & Electrical

If smells seem to come from specific vents, there may be blockages or leaks in the ductwork trapping moisture. For musty odors, consider having your evaporator coils and ducts professionally cleaned. This service usually costs between $150 and $780, but it can eliminate mold, restore proper airflow, and improve dehumidification – helping your system run more efficiently and saving you money in the long run.

Inspect and Replace Air Filters

The air filter plays a crucial role in keeping your HVAC system running efficiently. When filters get clogged with dust, pet hair, and other debris, they restrict airflow. This forces your system to work harder, which can spike energy use by as much as 15%. Not only does this increase your utility bills, but it also puts unnecessary strain on your system.

“A dirty filter will slow down air flow and make the system work harder to keep you warm or cool – wasting energy.” – Energy Star

A clogged filter can also lead to short cycling and cause dust to build up on internal components, further reducing performance. Since dirt and neglect are leading causes of HVAC system failure, keeping your air filter clean is a simple yet essential step to maintain efficiency and extend the life of your system. Here’s how you can check and manage your air filter to keep everything running smoothly.

How to Check Air Filter Condition

Regular maintenance not only cuts down on wasted energy but also helps your system last longer. Checking your air filter is quick and can save you money in the long run. Start by locating the filter slot, which is usually found in the air handler or behind a return air grill. Before handling the filter, make sure to turn off your HVAC system at the thermostat to avoid any injuries or debris being pulled into the system.

Next, remove the filter and hold it up to a light source. If little to no light passes through, it’s time to replace it. Even if the filter doesn’t appear completely clogged, a gray or brown tint means enough buildup has occurred to restrict airflow and waste energy. While the filter is out, take a moment to check for dust around the surrounding area. Excess dust can quickly clog a new filter.

How Often to Replace Filters

Inspect your filter monthly and aim to replace it at least every three months. However, certain household factors might require more frequent replacements. Homes with shedding pets, wood-burning fireplaces, or those located in high-pollution areas may need filter changes every 60 days. During peak heating or cooling seasons, when your system is running constantly, filters could clog as quickly as 30 days.

The type of filter you use also determines its lifespan:

- Flat or fiberglass filters: Replace every 30 days

- Pleated filters: Last 90 days to 4 months

- HEPA filters: Replace annually

- Washable filters: Clean monthly

When installing a new filter, make sure the arrows on the frame point toward the blower motor to ensure proper airflow. If your filter slot doesn’t have a cover, seal any gaps with duct tape or a magnetic cover to prevent air leaks.

For professional HVAC maintenance and energy-saving solutions, contact Hydrodynamics. They can help keep your system running efficiently year-round.

Review System Age and Repair Records

Taking a closer look at your HVAC system’s age and repair history can reveal inefficiencies that might be draining your wallet.

If your system is more than 10–15 years old, it’s likely missing modern energy-saving technology. Air conditioners and heat pumps generally last 10–12 years, while furnaces can operate for 15–20 years. Once these systems surpass their expected lifespans, their efficiency tends to drop significantly.

Switching to an ENERGY STAR certified unit could help you save up to 20% on heating and cooling costs compared to a heat pump or air conditioner that’s a decade old. Additionally, older systems often suffer from component wear, which can lead to energy-wasting issues like short-cycling and even damage critical parts like the compressor.

Check Your System’s Age

You can find the installation date on the manufacturer’s label located on your indoor or outdoor unit. If your air conditioner or heat pump is over 10 years old, or if your furnace or boiler is older than 15 years, it’s time to have it inspected by a professional.

Older systems may also lack features like variable-speed motors and smart controls that help optimize energy use. If your system still uses R-22 refrigerant (commonly known as Freon), it’s a good idea to replace it. R-22 is being phased out, making repairs not only more difficult but also increasingly expensive.

Review Repair History and Costs

Take a moment to review your repair records. Frequent breakdowns and rising energy bills are clear indicators of a system losing its efficiency. A helpful guideline is the “$5,000 Rule”: multiply your system’s age by the cost of a repair. If the result exceeds $5,000, replacing the system is typically the smarter financial decision.

For example, if a 12-year-old air conditioner requires a $500 repair, the total ($6,000) suggests replacement is the better option. Another rule to consider is the “50% rule”: if a single repair costs 50% or more of what a new system would cost, replacement is usually the way to go.

Keep an eye out for signs like uneven temperatures, unusual noises, or rapid on-and-off cycling. These issues often point to deeper problems and should be addressed by a professional. For expert advice on your system’s condition, reach out to Hydrodynamics.

When to Contact a Professional

While you might be able to identify some energy inefficiencies on your own, many problems stay hidden without the help of certified technicians equipped with specialized tools. After addressing visible issues, professionals can uncover deeper problems that aren’t immediately apparent.

Professional Testing for Hidden Problems

HVAC technicians use tools like manometers and flow hoods to measure air pressure and airflow at vents. These tools help detect blockages, undersized ducts, or loose joints that can lead to uneven temperatures in your home.

Duct leaks are another frequent source of energy loss that often go unnoticed without a professional inspection. These leaks can waste 20%–30% of conditioned air, especially in unconditioned areas like attics or basements. Experts address these leaks with long-lasting solutions, such as mastic sealant or metal-backed foil tape, which are far more effective than regular duct tape.

Refrigerant issues also demand professional attention. Even a small refrigerant loss – around 10% – can increase your annual energy costs by as much as 20%. Simply topping off refrigerant is a short-term fix and can become an expensive habit.

Other hidden issues, like loose electrical connections, dirty blower wheels, or gaps in insulation, can also impact your system’s performance. Advanced diagnostic methods, such as those used by Hydrodynamics, can identify these energy-draining problems that might otherwise go unnoticed.

Professional inspections do more than just reveal hidden issues – they also provide actionable steps for effective maintenance.

Benefits of Regular Maintenance

Regular maintenance goes beyond fixing current issues; it also helps prevent energy waste from creeping back into your system. A clean and well-maintained HVAC system can operate with up to 15% less energy, potentially saving homeowners between $200 and $300 annually on energy bills.

“Dirt and neglect are the top causes of heating and cooling system failure and inefficiency.” – Denise Minor-Hoes, ENERGY STAR

Routine tune-ups ensure your system stays in peak condition by cleaning evaporator and condenser coils, fine-tuning airflow, lubricating moving parts, and calibrating thermostat settings. These steps reduce the strain on your system, which not only lowers energy usage but also minimizes wear and tear on its components.

Scheduling bi-annual maintenance – checking your cooling system in the spring and your heating system in the fall – can help catch minor problems before they escalate into costly emergencies. While an annual maintenance visit typically costs between $150 and $300, emergency repairs can range anywhere from $300 to over $1,000. Regular upkeep can also extend your HVAC system’s lifespan to 15–20 years, compared to just 10–12 years for systems that are neglected.

For a thorough energy efficiency evaluation or maintenance services, consider reaching out to Hydrodynamics. Their technicians offer specialized tests, such as duct blaster assessments and thermographic inspections, to ensure your HVAC system is running as efficiently as possible. These professional services are the perfect complement to your efforts to reduce energy waste and keep your home comfortable year-round.

Conclusion

Catching HVAC energy waste early can trim your energy bills by as much as 15%. Keep an eye on your monthly utility bills – unexplained spikes might be a red flag. Also, watch for warning signs like weak airflow, strange noises, or unpleasant odors, which could mean your system is overworking unnecessarily.

Regular maintenance is a game changer when it comes to efficiency. HVAC systems over 10 years old often lose their edge and may need replacing to keep operating costs under control.

“Addressing issues early can help you save up to 15% on your energy bills.” – U.S. Department of Energy

But maintenance isn’t the only piece of the puzzle. Energy waste can stem from leaky ducts, poor insulation, or blocked vents. Sealing and insulating ducts alone can improve efficiency by up to 20%. And if you upgrade to an ENERGY STAR® certified smart thermostat, you could save around $100 annually.

If routine checks and maintenance don’t completely solve the problem, it’s time to bring in a professional. Hydrodynamics offers advanced diagnostic services to uncover hidden issues like duct leaks or refrigerant loss – problems that DIY fixes often overlook. Whether it’s routine upkeep or a professional inspection, taking action now can help you cut energy costs, extend your HVAC system’s lifespan, and keep your home comfortable throughout the year.

FAQs

How can I tell if my HVAC system is outdated and inefficient?

If your HVAC system has been around for more than a decade, it might be worth checking if it’s still running efficiently. Common signs that your system may be outdated include rising energy bills, frequent repairs, and inconsistent indoor temperatures. Most air conditioners and heat pumps are built to last about 10–12 years, so if yours is approaching or exceeding that age, it may not be performing at its best.

Older systems often have trouble maintaining steady performance, which can result in frequent on-and-off cycling or certain rooms feeling too hot or too cold. Upgrading to a modern, energy-efficient HVAC system can reduce utility costs and create a more comfortable environment in your home or business.

What are the warning signs that my HVAC system needs maintenance?

Your HVAC system often sends out clear signals when it needs professional care. Be alert for unusual sounds like rattling, squealing, or grinding. Pay attention to strange smells, such as a burning odor or a musty scent, and watch for temperature inconsistencies that don’t match your thermostat settings. Other red flags include uneven heating or cooling, frequent cycling (when the system keeps turning on and off), or unexpected spikes in your energy bills.

When these issues pop up, it’s time to bring in a professional. A qualified technician can handle tasks like cleaning components, replacing filters, calibrating sensors, and inspecting ductwork to get your system back to peak performance. Regular maintenance not only helps avoid expensive repairs but can also reduce your utility bills. Hydrodynamics provides expert HVAC maintenance services to ensure your system stays efficient and reliable all year long.

How often should I change my HVAC air filter to keep it running efficiently?

To keep your HVAC system running smoothly, make it a habit to replace the air filter regularly. Inspect the filter monthly, especially during high-usage times like summer and winter. If it looks dirty, don’t wait – replace it right away.

Most filters need to be swapped out at least once every 30 days. If your system sees lighter use, you might stretch this to three months, but even if the filter looks clean, replacing it every quarter helps prevent debris buildup that could overwork your system. If you have pets, smokers, or a lot of dust in your home, you may need to replace the filter more often – sometimes as frequently as every two weeks.

Changing your filter regularly not only improves airflow but also reduces energy waste and can extend the lifespan of your HVAC system.